Product realization is where ideas take their final shape and move from concept to tangible form. At this stage, design intent is translated into precise execution, ensuring that every element functions as envisioned. It is a process driven by accuracy, coordination, and respect for the original concept, resulting in furniture that feels coherent, purposeful, and refined.

This phase brings together design, materials, and technical expertise to create products that are both visually consistent and structurally sound. Careful planning and controlled execution allow each piece to evolve seamlessly from development to completion.

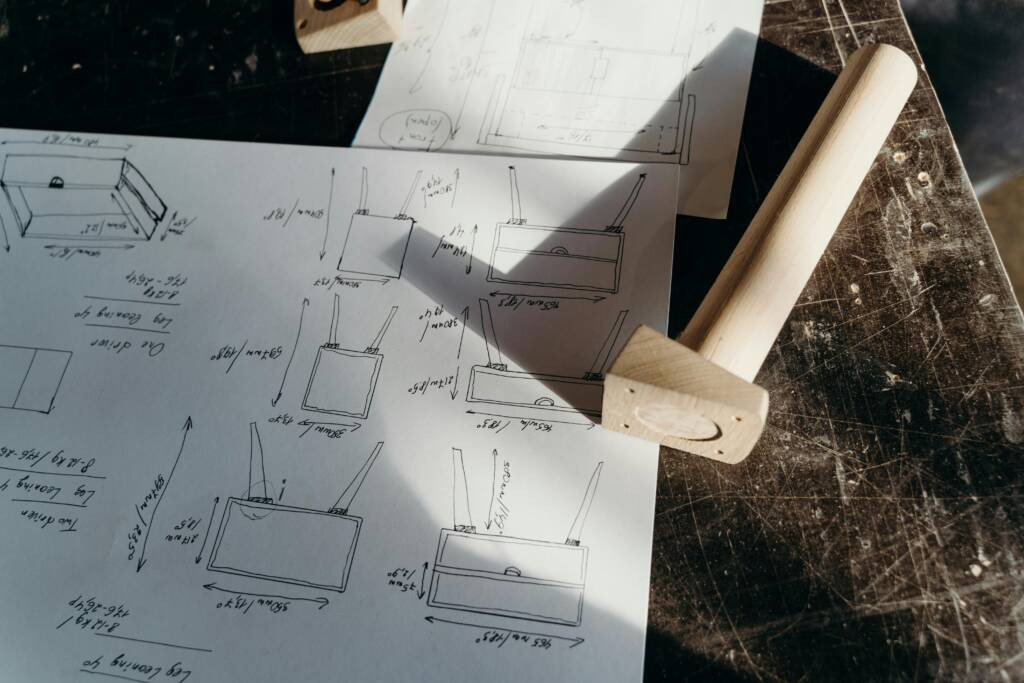

Technical Development & Prototyping

Technical development focuses on transforming visual concepts into build-ready specifications. Dimensions, construction methods, and functional details are carefully defined to ensure clarity and consistency throughout the realization process. Prototyping plays a key role, allowing designs to be tested, refined, and optimized before final production.

Through this iterative approach, proportions are validated, comfort is assessed, and structural integrity is confirmed. Adjustments are made with precision, ensuring that the final product reflects both aesthetic intention and practical performance.

Assembly & Quality Alignment

Assembly brings together individual components into a unified whole, guided by strict attention to detail. Each step is executed with care to maintain alignment, stability, and visual balance. The focus remains on achieving a clean, precise finish that reflects the integrity of the design.

Quality alignment ensures that the realized product remains true to its original vision. Finishes, joints, and surfaces are reviewed to confirm consistency and durability. This final alignment guarantees that every piece meets defined standards before moving forward to the next stage.